How Amazon FBA Works: Prep, Inbound Routing & Storage Fees

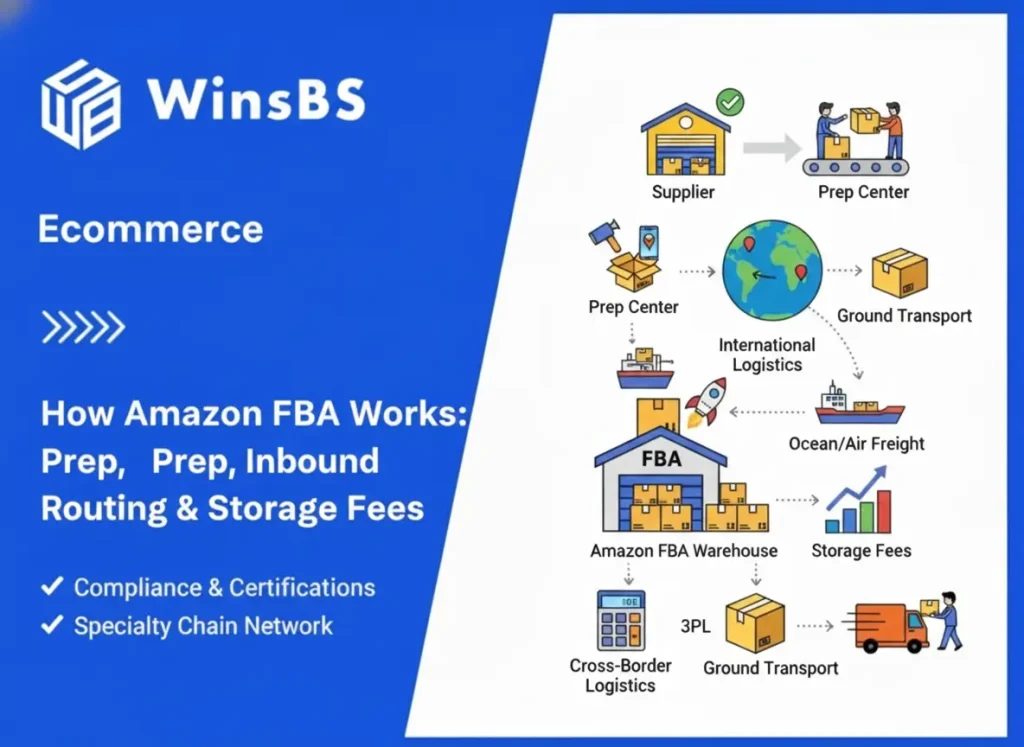

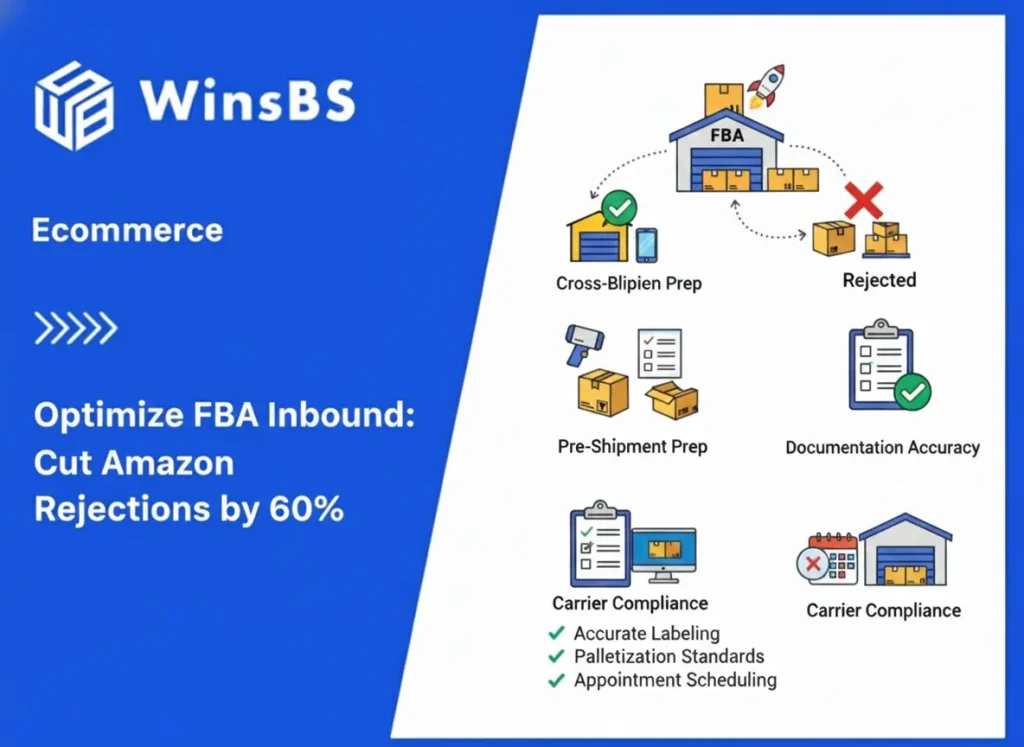

How Amazon FBA Works (2025–2026) What Sellers Must Know About Prep, Inbound Routing & Storage Costs Author: Maxwell Anderson, Editor-in-Chief, WinsBS Research Last updated: 2025 Focus: Amazon FBA workflow, prep requirements, inbound routing rules, storage fees, and cost/risk control for cross-border e-commerce sellers shipping into the United States. TL;DR Amazon FBA in 2025–2026 is no longer just “send cartons to a warehouse.” It is a tightly enforced system covering prep rules (labeling, packaging, carton and pallet standards), inbound routing (SPD, LTL, FTL with routing plans and appointments), and storage fees (monthly storage plus Aged Inventory Surcharge, AIS ). Amazon is ending its own FBA Prep services by early 2026 , has increased placement and inbound defect fees , and now charges extra for inventory that sits too long. If you still treat FBA as “ship as much as possible and let Amazon figure it out,” your margin will erode quickly. The brands that win treat FBA as a disciplined flow : prep outside Amazon, route in smaller, compliant batches, and keep only 30–45 days of stock in FCs while using a U.S. 3PL buffer like WinsBS for bulk storage and kitting. That is how you protect Prime speed without letting storage and inbound costs quietly consume your profit. WHAT AMAZON FBA IS & HOW THE SYSTEM WORKS IN 2025–2026 Amazon FBA was designed to solve a simple problem for sellers: “If I send inventory to Amazon, they will store it and ship it for me.” In 2025–2026, that simple story is still true at a high level—but the details have become much stricter and more expensive. At its core, Fulfillment by Amazon (FBA) means: You create FBA shipments in Seller Central or via API. You prepare, label, and pack units, cartons, and pallets according to Amazon’s rules. You route inventory into one or more fulfillment centers (FCs) using small parcel delivery (SPD), LTL, or FTL. Amazon receives and stows your units, then ships customer orders and handles basic customer service and returns. In exchange, you pay: Fulfillment fees per order (pick, pack, outbound shipping to the customer). Monthly storage fees based on cubic feet and time of year. Aged Inventory Surcharge (AIS) when inventory sits beyond specific age tiers. Placement and inbound-related fees when Amazon redistributes units across FCs or shipments arrive with defects. For cross-border brands, FBA is both a growth engine and a risk amplifier . Prime eligibility and FBA Buy Box preference can lift conversion, but a single failure in prep, routing, or capacity planning can create: 7–15 day restock delays. Unexpected AIS and storage bills. Inbound defect charges and shipment rejections. Lost Best Seller Rank (BSR) and slower recovery after stockouts. To understand how Amazon FBA really works now, it helps to view it as a three-part system : Stage What Happens Key Risks Where Sellers Lose Margin 1. Prep Units are labeled, bagged, bundled, and cartonized according to FBA rules. Mislabeling, mixed-SKU cartons, fragile items under-protected. Rejections, rework, inbound defect fees, delayed check-in. 2. Inbound Routing Shipments are routed to FCs via SPD/LTL/FTL with routing plans and appointments. Wrong box size, weight or pallet standards, missed appointments. Extra carrier fees, detention at cross-dock, inbound defect penalties. 3. Storage & Flow Units are stowed; orders ship; aging inventory triggers AIS tiers. Overstocking, slow-moving ASINs, poor forecasting. High storage and AIS, restock limits, forced removals. If you manage these three stages deliberately, FBA behaves like a predictable engine. If you treat them as background details, FBA becomes an expensive black box sitting between your factory and your buyers. FBA PREP REQUIREMENTS (2025–2026 UPDATE) FBA prep used to be simpler. In 2025–2026, Amazon has tightened every rule around packaging, labeling, carton specs, pallet specs, and shipment accuracy —and Amazon is ending its internal FBA Prep services by early 2026 . That means: All prep must be done correctly before inventory reaches the FC. Amazon will not fix your issues. They will reject, charge, or delay the shipment. 1. Unit-Level Prep Requirements Every individual sellable unit must meet the following standards: FNSKU barcode must be scannable and not covered by other barcodes. Suffocation-warning polybags required for loose items or small textiles. Bubble wrap required for fragile units. Items with sharp edges must be securely protected . Expiration-dated goods must have MM-DD-YYYY printed and visible. Amazon grades prep accuracy heavily. Repeated issues increase your defect rate and lead to inbound defect fees . 2. Carton Requirements (2025 Update) Amazon increased its carton dimension limits in 2025: Maximum length: 36″ (up from 25″) Maximum side lengths: 25″ × 25″ Maximum carton weight: 50 lbs unless marked as “Team Lift” or “Mechanical Lift” Cartons violating these limits are frequently: Refused at the FC. Returned at your expense. Subject to inbound defect fees . 3. Pallet Requirements (2025–2026) Standard pallet size: 40″ × 48″ Maximum pallet height: 72″ including pallet Maximum pallet weight: 1,500 lbs Pallets must meet GMA Grade B+ or better Mixed-SKU pallets require proper labeling and must follow Amazon’s mixed-carton rules Non-compliant pallets face: Appointment cancellation Rejection at dock Re-delivery fees Delay penalties 4. Labeling Requirements All cartons and pallets require properly placed labels: FBA carton labels (2 per carton, opposing sides) Pallet labels (4 sides) SPD/LTL/FTL carrier labels Fragile indicators when necessary Improper placement or low print quality leads to scan failures and lost shipments. 5. Documentation Requirements Amazon increasingly checks: Carton content accuracy SKU-level quantities ASN matching Routing plan consistency Mismatches trigger manual review and receiving delays. HOW TO PREP YOUR INVENTORY FOR FBA — STEP BY STEP The workflow below represents what high-performing cross-border brands follow in 2025–2026. It reduces inbound defects, prevents rejections, and keeps replenishment cycles predictable. Step 1 — FNSKU Assignment & Packaging Decisions Before production finishes, confirm: Whether each SKU uses manufacturer barcode or FNSKU Required protective materials Whether variations need bundling Packaging thickness to survive U.S. carrier handling Step 2 — Factory-Level Labeling (If Possible) The cheapest and most accurate place to apply FNSKU is the factory. If the factory cannot