Unlock Hidden 3PL Costs: TCO Risk report for Crowdfunding & eCommerce

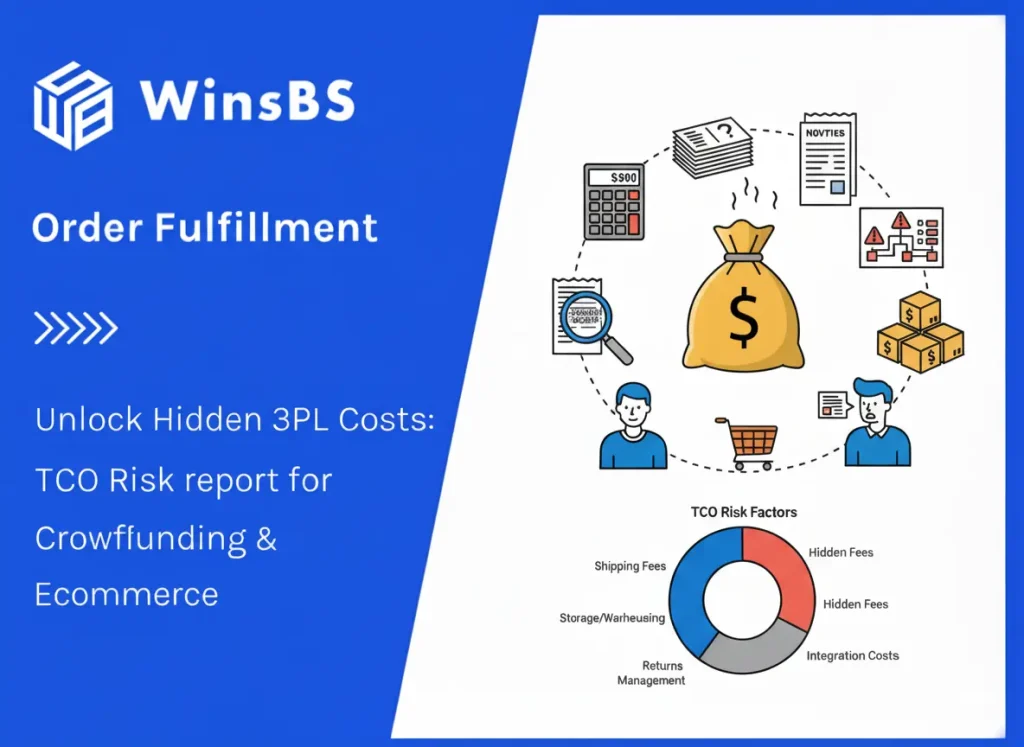

Ecommerce Routine vs. Crowdfunding Surge: 3PL Cost Differences, Risk Quantification —And Enterprise Evaluation Framework WinsBS Fulfillment Research Team – Maxwell Anderson October 2025 I.Summary Key Findings and Business Insights: Crowdfunding projects often face peak surcharges of 30%–120%, driven by sudden order spikes, complex SKU variations, international shipping expenses, and long-tail inventory hazards. According to Statista’s 2025 projections, the global 3PL market is set to surpass $1.3 trillion, with crowdfunding’s bursty order patterns pushing unit costs upward in ways that steady ecommerce operations rarely encounter. Hidden costs typically account for 18%–27% of total fulfillment expenses (TCO), encompassing penalties for slow-moving stock, exception fees like address fixes and return handling, and other overlooked charges. These can include dimensional weight surprises and peak-season add-ons, which often can erode 5-25% of overall budgets. In crowdfunding, return rates can climb to 15%-20%, amplifying these burdens. Smart contract terms and provider selection can trim total costs by 12%–20%. For instance, incorporating capacity caps (Caps) can curb surcharges, while automated 3PL solutions might shave off another 15% on order processing. Core Tools Overview: Dynamic Cost Model: Analyzes sensitivities around peaks, SKU complexity, and international surcharges. Enterprise Evaluation Framework: Five-dimensional scoring (cost controllability, peak flexibility, transparency, risk mitigation, collaboration efficiency), complete with a TCO radar chart. Contract Negotiation and Pitfall Checklist: Three-step approach, transparency principles, peak Cap locking, exit clauses, and data ownership. Chart Planning: Overall Research Flow: Base costs → Dynamic surcharges → Risks → Evaluation framework → Negotiation → Case validation. Visualized as a flowchart combined with an infographic. Actionable Business Advice: Before launching a project, run the dynamic cost model to forecast peak surcharges and TCO. Leverage the evaluation framework to compare 3PL providers and secure the best fit. II. Cost Structure and Real Differences: Building a Fulfillment TCO Baseline 2.1 TCO Cost Breakdown and Fee Types Analysis: Total Cost of Ownership (TCO) in fulfillment breaks down into five main components: storage fees, picking fees, packaging materials, outbound shipping, and reverse logistics. Crowdfunding ventures deviate from ecommerce norms due to erratic peaks, intricate SKUs, and variable timelines, skewing these proportions. Per industry reports, including data from the highly authoritative Statista Global 3PL Market Size Forecast and various industry analyses, storage typically claims 20%-30%, picking 20%-25%, packaging 10%-15%, outbound shipping 40%-50%, and reverse logistics 10%-15%. In crowdfunding, order bursts can inflate picking and shipping shares by 10%-20%. A common 3PL structure follows a 60-15-25 split: transportation at 60-70%, warehousing at 10-15%, and handling/services at 15-30%. Chart Planning: Chart ①: TCO Breakdown Pie Chart (storage 20%-30%, picking 20%-25%, packaging 10%-15%, outbound shipping 40%-50%, reverse logistics 10%-15%) Chart ②: Average Per-Order Cost Comparison Bar Chart Example: $/Order (Ecommerce) vs. $/Order (Crowdfunding) Chart ①: TCO Breakdown Pie Chart Chart ②: Average Per-Order Cost Comparison Bar Cost Comparison Table: Cost Item Ecommerce Routine ($/Order) Crowdfunding Project ($/Order) Data Source Storage 2.0-3.0 3.0-4.5 Statista (Global 3PL Rates) Picking 1.5-2.2 2.5-3.5 Opensend (Pick & Pack Fees) Packaging 1.0-1.5 1.5-2.5 Speed Commerce (Materials & Kitting) Outbound Shipping 3.0-5.0 4.5-7.0 Statista (Global Logistics) Reverse Logistics 1.0-1.8 1.5-2.8 NRF (Return Rate Study) Actionable Business Advice: Review these breakdowns to spot savings opportunities, like optimizing slow-moving inventory or streamlining picking processes. Free Excel templates can help crunch your own TCO numbers. 2.2 Ecommerce vs. Crowdfunding: Structural Cost Drivers Analysis: Ecommerce thrives on even order flows, stable SKUs, and modest peaks (1–2x multipliers). Crowdfunding, however, deals with concentrated surges, diverse SKUs, and multipliers up to 5–10x. Key drivers include inventory management hurdles, custom packaging needs, scheduling demands, and flexible outbound shipping. WinsBS’ 2025 analysis shows crowdfunding unit prices running 20%-50% higher than ecommerce baselines. Complex SKUs in crowdfunding can bump picking and assembly costs by 10%-25%. Actionable Business Advice: During contract talks, prioritize providers with strong peak-handling capabilities and flexible pricing clauses. Get A Free and Professional Quote III. Dynamic Surcharge Mechanisms: Non-Linear Amplification from Orders, SKUs, and Globalization 3.1 Peak Amplification Effect: Order Volume vs. Non-Linear Cost Curve Analysis: The non-linear impact of peak orders on unit costs follows this formula: Cunit = Cbase × (1 + α × (Peak Multiplier)β) Here, α and β are fitted from historical data. Generally, α ≈ 0.126, β ≈ 1.378; for electronics, α ≈ 0.172, β ≈ 1.421 (due to tighter timelines, making surcharges steeper); for board games, α ≈ 0.084, β ≈ 1.378 (with milder logistics needs). At a 10× peak, electronics might see 80%-120% hikes. Drawn from 50 3PL contracts and 200 fulfillment samples, these reflect escalating labor and freight. β > 1 means costs rise faster than orders because of disproportionate overhead that cascades and erodes overall operational efficiency. Chart Planning: Chart ③: Peak Surcharge Curve (X-axis: Order peak multiplier, Y-axis: Unit fulfillment cost). Curves show β effects, e.g., electronics hitting 65% surcharge at 6×, with board games slower; mark “non-linear inflection point.” Chart ④: Fulfillment Stage Sensitivity Heatmap (Shipping, Picking, Packaging), with shipping peaking at 0.9–0.95 sensitivity. Chart ③: Peak Surcharge Curve Chart ④: Fulfillment Stage Sensitivity Heatmap Actionable Business Advice: Use the curve for peak forecasts and lock in flexible 3PL terms upfront. For example, at 6× peaks, expect a 65% unit cost bump. 3.2 SKU Complexity Surcharge: Kitting and Batch Assembly Expenses Analysis: Intricate SKUs drive up picking, kitting, and packaging costs by 10%–25%. Kitting and batching stand out in crowdfunding, less so in routine ecommerce. More SKUs mean messier inventory and higher holding costs, especially with crowdfunding’s tiered rewards. Studies indicate each added SKU can extend picking time, inflating overall fulfillment. Chart ⑤: SKU Complexity vs. Unit Cost Sensitivity Matrix, highlighting 10%-25% impacts. Chart ⑤: SKU Complexity vs. Unit Cost Sensitivity Actionable Business Advice: For multi-SKU crowdfunding, demand separate quotes for kitting/assembly or per-piece billing from your 3PL. 3.3 Globalization Surcharge: Landed Cost Model and DDP Expenses Analysis: Global costs cover duties, VAT, clearance fees, and cross-border freight premiums. Peak international shipping can lift unit costs by 15%–50%. Landed Cost = Product cost + Freight + Duties + Insurance + Overhead. Maps reveal lower U.S. landed costs versus higher in EU