HTS Classification Guide for Cross-Border E-commerce Sellers

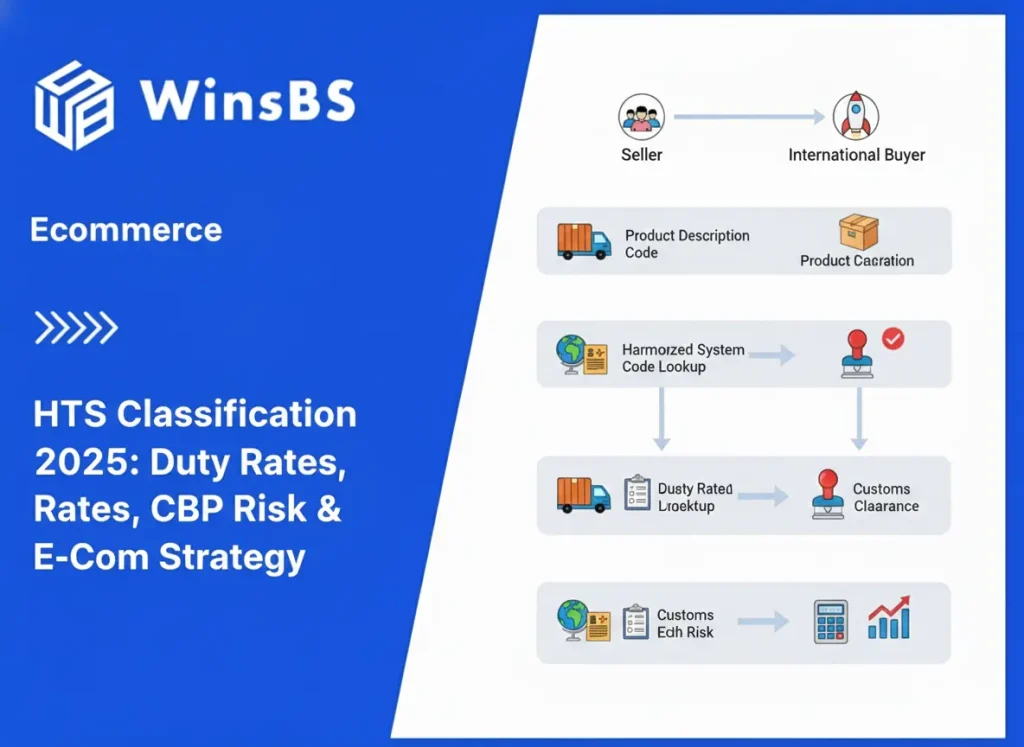

HTS Classification Guide for Cross-Border E-Commerce Sellers How Tariff Codes Shape Your Duty Costs, Risk Profile, and U.S. Fulfillment Strategy Author: Maxwell Anderson, Editor-in-Chief, WinsBS Research Last updated: 2025 Focus: HTS classification for cross-border e-commerce brands, enforcement patterns, category-specific risks, and how tariff decisions impact U.S. fulfillment design. TL;DR HTS classification is not a paperwork detail. It is the legal switch that turns duty rates, Section 301 exposure, Partner Government Agency (PGA) rules, and inspection risk on or off. For e-commerce brands shipping from Asia into the U.S., the HTS code on your commercial invoice does three things: it sets your landed cost, it decides how often CBP looks at your cargo, and it determines how flexible your DDP, Section 321, and U.S. fulfillment options really are. Relying only on factory-suggested codes or “whatever the forwarder used last time” is how brands end up with retroactive duty bills, detained shipments, and broken unit economics. This guide explains how HTS actually works in practice, how to build a classification workflow your team can maintain, and where a U.S. fulfillment partner like WinsBS fits into that system. WHY HTS CLASSIFICATION SITS ABOVE FREIGHT AND FULFILLMENT Most cross-border brands start with the obvious levers: freight quotes, 3PL price sheets, and last-mile carrier tables. HTS classification is treated as a fixed input — something the factory or broker “handles.” In reality, HTS is the upstream variable that quietly drives all of those downstream costs and risks. In a typical workflow, HTS codes only appear in a few visible places: the commercial invoice, the packing list, the entry summary, and the customs broker worksheet. But behind those documents, the code you pick controls: The duty rate that flows into every landed cost and pricing model. Whether Section 301 adds another 7.5–25% on top of the base duty. Which PGAs — FDA, CPSC, FCC, USDA, EPA — have jurisdiction over your product. How CBP’s targeting systems score your shipments on a low-risk vs high-risk scale. Whether your DDP pricing and “taxes and duties included” promise is actually sustainable. For small parcel flows, Section 321 models, and crowdfunding campaigns, these questions are often ignored until something breaks: a shipment is detained, a large B2B customer audits your tariff treatment, or a broker warns that your codes do not match comparable products in the market. At that point, the cost of fixing the problem is higher, and the damage to timelines is already done. For cross-border teams managing U.S. operations from 8,000–12,000 kilometers away, the HTS decision has extra weight. A wrong code can freeze containers at the port, delay FBA replenishment, and stall outbound fulfillment from your U.S. 3PL all at once. That is why this guide treats HTS classification as part of your fulfillment and inventory strategy, not just a customs formality. HS VS HTS: HOW THE TARIFF SYSTEM REALLY WORKS Sellers often use “HS code” and “HTS code” as if they were interchangeable. They are related, but not the same. The distinction matters if you are shipping into multiple markets or relying on suppliers who mostly export to regions outside the U.S. The global framework is the Harmonized System (HS), managed by the World Customs Organization (WCO). HS provides: A standardized six-digit structure (chapters, headings, subheadings). Section and chapter notes that define the logic of each group. A shared language for customs authorities, importers, and exporters worldwide. The first six digits of your code are therefore “global.” A pair of wireless earbuds, a cotton T-shirt, or a toy building set should fall under the same six-digit HS base in any country that follows WCO rules. In the United States, those six digits are extended into the Harmonized Tariff Schedule of the United States (HTSUS): Digits 1–6: HS core, aligned with the global Harmonized System. Digits 7–8: U.S.-specific subheadings with their own legal text. Digits 9–10: Statistical subdivisions used for trade data and reporting. This is why two countries can agree on the same six-digit HS code but apply very different duty rates and rules in the last four digits. An EU tariff sheet or a UK-based classification can be a good starting reference, but it is not a substitute for reading the U.S. HTSUS text. For U.S. purposes, the HTSUS has the force of law. It is backed by statute and cross-referenced in customs regulations. CBP officers, import specialists, and auditors work from this schedule when they: Reclassify shipments they believe were misdeclared. Assess additional duties, including Section 301 where applicable. Determine whether other regulatory frameworks and PGAs are triggered. Evaluate whether the importer exercised “reasonable care” in classification. For cross-border e-commerce brands, the practical takeaway is simple: HS gets you into the right neighborhood; HTS puts you in a specific house with a specific tax bill and risk profile. Treating a non-U.S. tariff sheet as the final answer is one of the most common failure points in classification. GENERAL RULES OF INTERPRETATION (GRI) IN PLAIN LANGUAGE When CBP and brokers decide how to classify a product, they are not improvising. They are following the General Rules of Interpretation (GRI) built into the HTSUS. Understanding these rules is what turns classification from guesswork into a repeatable, defensible process. GRI 1 — Legal Text Over Titles GRI 1 states that section, chapter, and subchapter titles are for reference only. Classification is determined by the wording of the headings and any relevant section or chapter notes. In practical terms, this means: You cannot classify a “smart lamp” in a heading just because “lamps” appear in a chapter title. You must read the exact heading and its notes to see what is included or excluded. Marketing names do not control classification; the legal text does. For e-commerce teams, the takeaway is that catalog names, Amazon listing titles, and branding language are almost irrelevant to HTS decisions. The only thing that matters is what the product is and what it does according to the legal notes. GRI 2(a) — Unassembled and Incomplete Goods GRI 2(a) deals with products