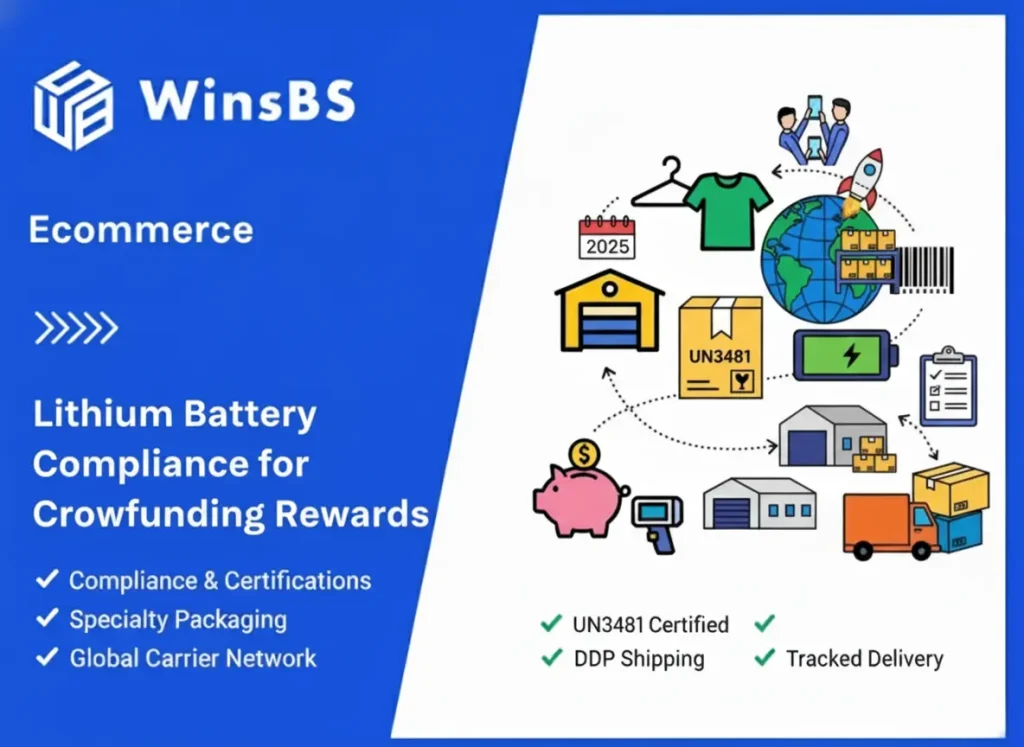

Lithium Battery Compliance for Crowdfunding Rewards

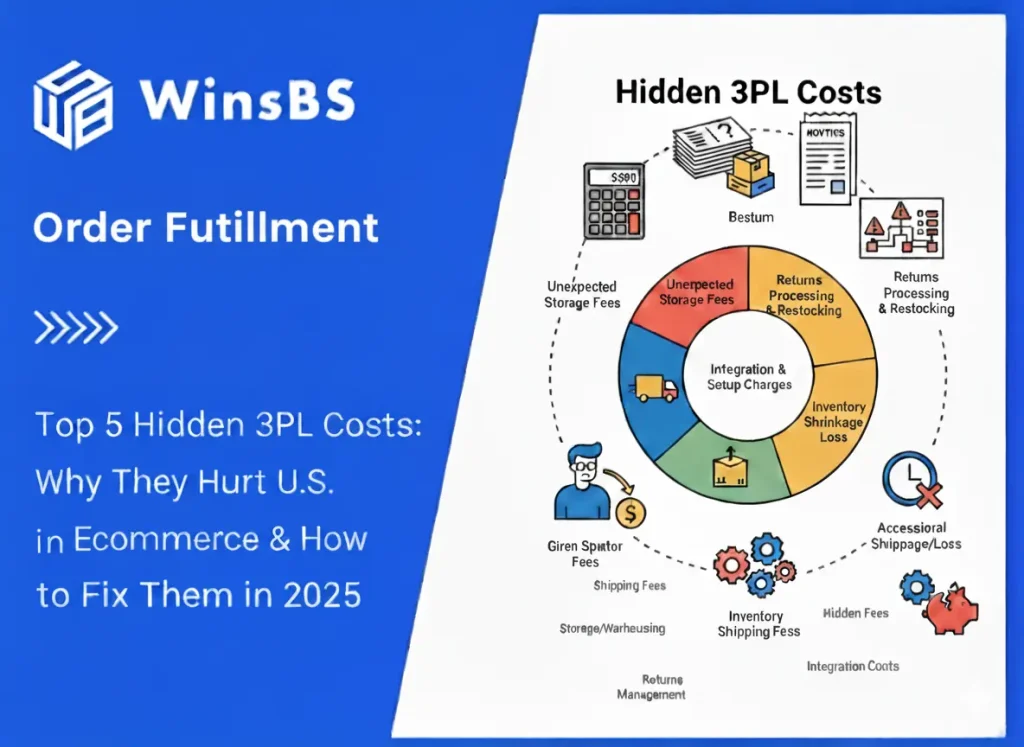

Lithium Battery Compliance for Crowdfunding — 2025 Guide The Hidden Risk Behind Global Rewards Shipping A Practical Playbook for Kickstarter, Indiegogo & Gamefound Creators WinsBS Fulfillment Research Team – Maxwell Anderson November 2025 Executive Summary Overview: Battery Compliance Is Now the First Gate in Global Rewards Shipping If your Kickstarter or Indiegogo campaign includes any type of lithium battery—built-in, removable, or simply sitting inside the box—your project enters one of the most heavily regulated categories in cross-border shipping. Kickstarter’s 2025 tech review shows that over 30% of electronics campaigns contain lithium batteries, yet most creators only learn the rules after a carrier rejects pickup or customs stops an entire batch. Lithium batteries aren’t “hard” to move. They’re hard to move when the documentation isn’t aligned with aviation and customs rules. A factory safety test does not guarantee air approval. Air approval does not guarantee customs approval. And clearing customs doesn’t automatically authorize delivery into 80+ countries. This guide distills what WinsBS has learned from 500+ battery-inclusive crowdfunding projects (2023–2025): from paperwork mismatches that caused last-minute refusals, to route failures in the EU and Australia, to full recovery operations that brought delayed shipments back on track. If your priority is simple—delivering rewards on time without upsetting backers—this is the reference U.S. creators wish they had before launch day. Core Findings: Where Battery Projects Fail—and Why Factory tests ≠ transport compliance: Factories test for product safety, not aviation laws. Expired or outdated UN38.3/SDS files remain the single biggest reason DHL, UPS, and FedEx refuse battery shipments. Section 321 suspension increases manual checks: As of Aug 29, 2025, 321 de minimis is suspended for commercial imports. Battery products are now pulled for inspection far more often—even if the shipment value is low. Acceptance varies dramatically by region: Hong Kong and Taiwan handle battery parcels reliably. U.S. warehouses face stricter outbound checks. Australia requires mandatory SoC restrictions and performs frequent inspections. Documentation mismatches drive 15–20% failure rates: Incorrect Wh declarations, wrong HS codes (especially 8507), outdated SDS formats, and missing labels are the most common triggers for EU/UK/AU delays. Crowdfunding ≠ ecommerce: Shipping to 60–120 countries in a single wave multiplies compliance touchpoints that normal Shopify or Amazon operations never see. The point many creators miss: delays rarely come from the battery itself—they come from paperwork sequencing, packaging decisions, and route selection. Key Recommendations: How Creators Avoid Battery-Driven Delays Step 1 — Run a pre-launch compliance check: Validate UN38.3 (100Wh batteries. 9/10 Taiwan → U.S./EU Stable outbound inspection; predictable battery handling; high reliability for mid-sized campaigns. Slightly slower EU processing; limited postal flexibility for battery parcels. 8/10 Mainland China → Direct Air Strong price competitiveness; deep manufacturing integration; fast entry for U.S.-bound shipments. Strict document checks; higher “documentation mismatch” returns; occasional route downgrades to ground. 5/10 EU Hubs (Germany / Netherlands / Belgium) Germany = consistent, stable inspections. Netherlands = flexible battery handling. Belgium = strong for EU DDP flows. Occasional HS 8507 flagging; EU states differ in supplemental SDS requests. 7/10 Australia Predictable once accepted; ideal for local backers requiring ground-based redistribution. Extremely strict lithium rules; mandatory SoC limits; high return rate if labels aren’t perfect. 3/10 Canada Strong U.S.–Canada routing; predictable ground networks; smooth processing under 100Wh. Supplemental SDS requests for >100Wh batteries; inconsistent peak-season inspections. 6/10 Key Takeaway: The “correct” route isn’t the cheapest — it’s the one that aligns with your battery type, documentation, and target countries. Using a hub with strong lithium acceptance (HK/TW) dramatically lowers the chance of mid-route rejections or customs delays. 7 Common Battery Compliance Pitfalls in Crowdfunding (With Real Cases) Even well-prepared campaigns run into battery issues—not because the product is unsafe, but because global carriers and customs offices expect paperwork, labeling, and routing to match their exact standards. After supporting hundreds of battery-inclusive Kickstarter and Indiegogo projects, these are the seven failure patterns we see most often. The 7 Pitfalls That Derail Battery Shipments Pitfall What Actually Happens Typical Impact on Creators 1. No UN38.3 Report Carrier system flags the battery as untested; DHL/UPS refuse pickup immediately. Shipment returned to origin; creators lose 1–2 weeks and pay $1K–$3K in fees. 2. Expired UN38.3 Batteries technically “safe,” but treated as unverified if report is older than 12 months. Warehouse hold + reinspection; backers receive delays of 2–6 weeks. 3. SDS Not in GHS Format UPS/FedEx instantly reject outdated SDS templates from factories. Forced reissue of SDS; campaign loses 5–10 days during relabel and reapproval. 4. Missing or Incorrect IATA Battery Labels Cargo inspectors flag parcels; route gets downgraded from air → ground. Shipping times double; costs increase 15–30% depending on lane. 5. Wrong Watt-Hour (Wh) Declaration Carrier reclassifies shipment as “hazmat” or forces manual verification. Unexpected hazmat fees; 7–14 day delay; EU lanes heavily impacted. 6. Using Postal Routes That Don’t Accept Lithium National postal networks reject or destroy parcels containing lithium batteries. Zero recovery—backers never receive their rewards; campaign absorbs full loss. 7. Wrong HS Code (Especially 8507) EU/UK systems trigger extra checks or override DDP; backers are asked to pay duties. Backer frustration spikes; refund and support workload increases dramatically. Key Takeaway: These seven issues have almost nothing to do with the product itself. They’re paperwork, labeling, and routing decisions — and all of them are preventable with proper pre-shipment audits and a 3PL that understands global battery workflows. How a Specialized Crowdfunding 3PL (Like WinsBS) Prevents All These Issues Battery-inclusive campaigns don’t fail because creators lack effort — they fail because global carriers, customs offices, and regional hubs follow different playbooks. A standard ecommerce 3PL isn’t built for this. Crowdfunding requires workflows that anticipate document gaps, label mismatches, route restrictions, and country-by-country variations before shipments ever move. WinsBS built dedicated SOPs for Kickstarter, Indiegogo, and Gamefound campaigns from 2023–2025. The table below summarizes how these workflows directly neutralize the most common failure points. How WinsBS Removes Battery Shipping Risk Issue WinsBS SOP Outcome Missing / Expired UN38.3 Pre-flight document audit; expiration check; factory coordination to reissue compliant reports. Prevents DHL/UPS/FedEx rejection;