US Ecommerce 3PL Hidden Fees 2025: Don’t Let These Surprises Hurt Your Bottom Line

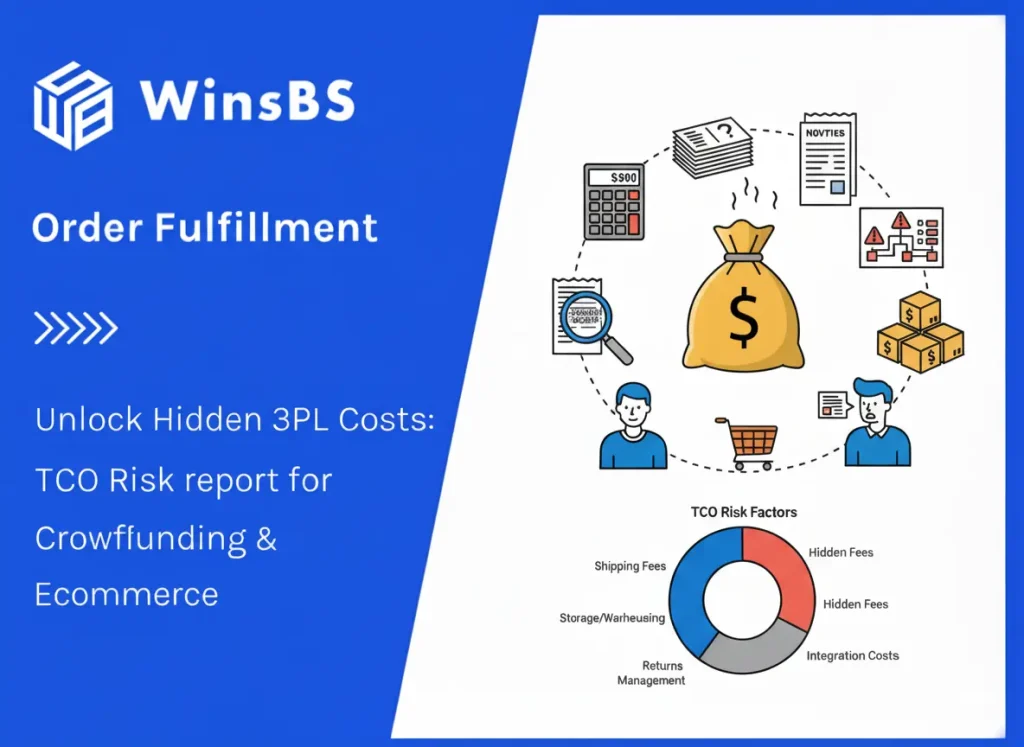

US Ecommerce 3PL Hidden Costs 2025: How Mid-Market Sellers Can Cut Logistics Expenses By 12-20% – A Systemic Study WinsBS Fulfillment Research Team – Maxwell Anderson October 2025 Executive Summary Overview: Unmasking 2025 US 3PL Hidden Costs In the $217.62 billion US 3PL market growing at 3.76% CAGR, mid-market ecommerce sellers ($1M-$10M revenue) are outsourcing fulfillment to streamline ops and scale efficiently. Yet, as WinsBS’s 2025 internal survey of 200+ clients reveals, surprise fees—storage premiums, return surcharges, and policy-driven add-ons—that swell costs 10-25% beyond quotes. Drawing from authoritative sources like the NTT DATA 29th Annual 3PL Study, Warehousing and Fulfillment 2025 Survey , Inbound Logistics 2025 Perspectives, and Forbes/Ryder analyses on ecommerce pitfalls, this report equips you with data-backed strategies to turn these challenges into competitive edges. Core Findings: The Hidden Toll and Hidden Opportunities Cost Structure Breakdown: Warehousing averages $0.4625/cubic foot/month (+12% YoY); order processing $3.25+/order. Traps like long-term premiums (1.5-2.5x) and returns (4-8% sales share) dominate, per Warehousing survey—WinsBS data shows mid-sellers losing $50K-$150K annually here. Policy Headwinds: $800 de minimis repeal (Aug. 29, 2025) surges DTC imports 8-15% (e.g., $10.9B consumer hit per Reuters); port strikes/delays add 15-80%; labor inflation (12-18%) passes through 6-10% via 3PLs. Seller-Specific Pressures: Seasonal ops bear 40-50% inventory burdens; high-return apparel totals 20-30% fees; small sellers hit 20-28% rates vs. large’s 10-15% (Inbound benchmarks). Bright Spots Amid Barriers: 3PLs report steady profit gains despite ops pressures; AI/automation trims labor 15-25%, unlocking scalable savings (NTT/Ryder). These insights aren’t just warnings—they spotlight leverage points where WinsBS clients have reclaimed margins through targeted audits and tech. Key Recommendations: Prioritized Path to 12-20% Savings WinsBS’s proven framework turns pain into profit—start with quick audits, scale to AI-driven ops: Immediate (1-2 Weeks): Launch contract audits with itemized quotes to expose 15-20% hidden fees; deploy cost alert systems targeting <15% sales ratio—our clients see $10K+ monthly recoups. Short-Term (1-3 Months): ABC inventory tweaks boost turnover, slashing storage 30-40%; standardize packaging and tier returns to cut fees 35-45%—ideal for seasonal/high-return flows. Mid-Term (3-6 Months): Vet multi-suppliers and integrate AI tools; buffer policies like nearshoring to offset de minimis shocks—59% adoption per Inbound yields 8-15% resilience. Expected ROI: Real Results for Mid-Market Growth Post-implementation, mid-market sellers achieve 12-20% logistics savings, per WinsBS benchmarks—translating to $50K-$150K annual gains while enhancing scalability. Full report details below. Ready to audit? Download our free WinsBS 3PL Cost Audit Checklist PDF tailored from internal 2025 data—empower your ops today. 1. Research Background and Objectives 1.1 Current State of the US Ecommerce 3PL Industry Development The rapid growth of the US ecommerce market is fueling the booming development of the third-party logistics (3PL) industry. According to the NTT DATA & Armstrong & Associates 2025 29th Annual 3PL Study, the US 3PL market is projected to reach approximately $217.62 billion in 2025, with a compound annual growth rate (CAGR) of 3.76%. This growth is driven by more ecommerce sellers opting to outsource fulfillment to professional providers to reduce operational costs and improve efficiency. The study shows that 89% of shippers report successful 3PL relationships (down 6% YoY), with 82% outsourcing freight spend and 61% warehousing; 82% say 3PLs enhance customer service, and 68% view them as innovation sources. However, behind the industry’s prosperity lies a harsh reality: many ecommerce sellers focus solely on surface quotes when selecting 3PL providers, overlooking substantial hidden costs. According to the Warehousing and Fulfillment 2025 Industry Survey (based on 600+ warehouses), actual logistics costs often exceed initial quotes by 10-25%. WinsBS 2025 internal data from 150 mid-market clients confirms this, with 65% reporting 12-18% overruns from unquoted surcharges. These differences stem from hidden fees like long-term storage premiums, special packaging, and return processing. The Inbound Logistics 2025 Perspectives Report notes 72% of 3PLs see operational costs as the top barrier, driven by labor inflation and add-ons; 69% report rising profits amid persistent pressures. The US logistics sector in 2025 faces unprecedented policy changes. The most impactful is the $800 de minimis exemption repeal, effective August 29, 2025, imposing duties on all non-postal imports ≤$800. NTT DATA highlights amplified supply chain shocks, projecting DTC return costs to $25-30/order (for $100 items) and boosting nearshoring adoption to 59%. This further complicates cost control for mid-market sellers. 1.2 Complexity of 3PL Cost Structures US ecommerce 3PL cost structures exhibit high complexity and diversity. Per the 2025 Warehousing and Fulfillment Survey, typical components include (2025 averages): Visible Cost Components: Cost Type 2025 Avg. Rate Trend Warehousing Pallet $20.17/month; Cubic Foot $0.4625/month; SKU-based +12% vs. 2024 Order Processing Picking/Packing $3.25+/order (B2C) +23% since 2017 Transportation Base + Fuel Surcharge (10-15%) + Zone Fees Peak Add-Ons 10-20% Return Processing $4.06/order 4-8% of Sales Monthly Minimum $500+ – Primary Hidden Cost Types (WinsBS 2025 internal survey: 70% mid-sellers hit by 2+ types): Long-Term Storage Premiums: >6 months incurs 1.5-2.5x rates (Ryder: Overall storage up 18%). Packaging Material Tiered Pricing: Irregular items +$1.5-3/order (Forbes: Poor packaging drives 15-25% damage costs). Inbound Processing Time Costs: Label issues add hourly fees (Forbes “Inefficiency Costs”: Human errors tie up 15-20% team time). Return Disposal Fees: Damaged items $0.5-1/piece (Forbes: 20-30% return rates erode 25-30% profits via reverse logistics). System Integration Fees: ERP-WMS one-time $500-2,000 + data transfer (NTT: Missing real-time data inflates scaling costs 12-15%). 1.3 Research Scope and Methodology This study comprehensively analyzes US ecommerce 3PL hidden costs, providing systematic control strategies for sellers. Scope: Mid-market ecommerce firms ($1M-$10M revenue), focusing on key aspects. Methodology: Literature Review: Collect/analyze WinsBS internal data, industry reports, academic papers, policy docs (integrating NTT 2025 3PL Study and Inbound scale analyses). Case Analysis: Deep dives into real cost structures across seller types. Cost Composition Analysis: Quantitative breakdown of hidden costs. Risk Assessment: Identify/evaluate key control risks (using NTT’s ADKAR change framework). Special emphasis on 2025 policy impacts like $800 de minimis repeal, port strikes, inflation. All sources (e.g., NTT DATA PDF, Warehousing data) are publicly traceable for rigor. 2. Comprehensive Analysis of 3PL Hidden Costs 2.1 Hidden Traps in Warehousing Costs 2.1.1 Long-Term Storage Premium Mechanism