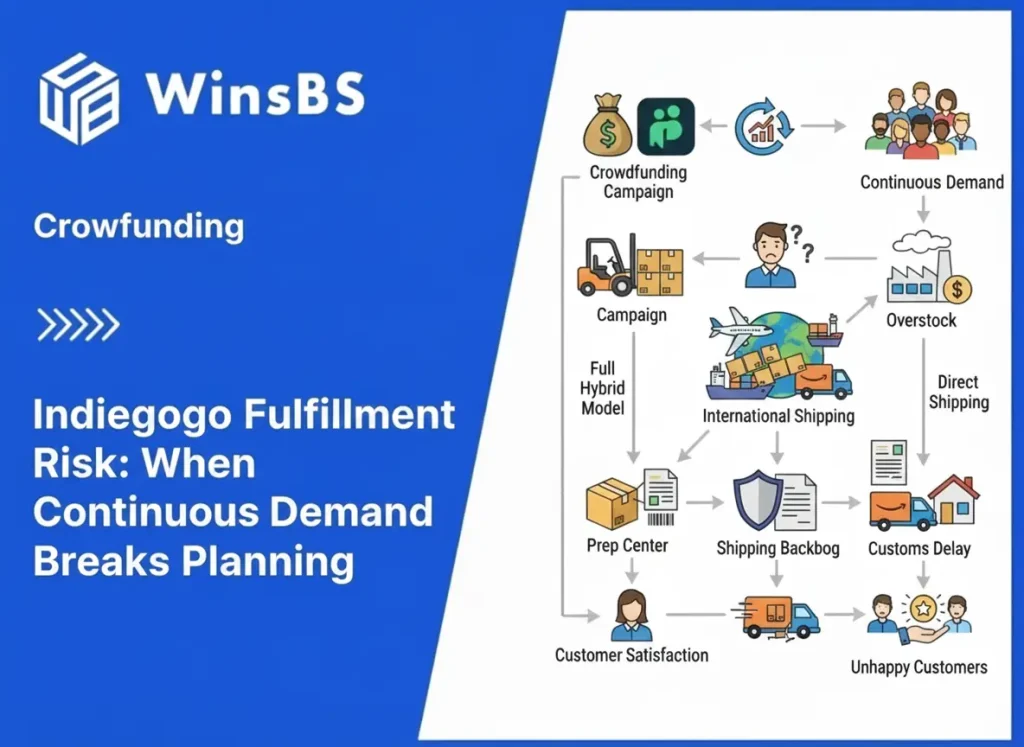

Indiegogo Fulfillment Risk: When Continuous Demand Breaks Planning

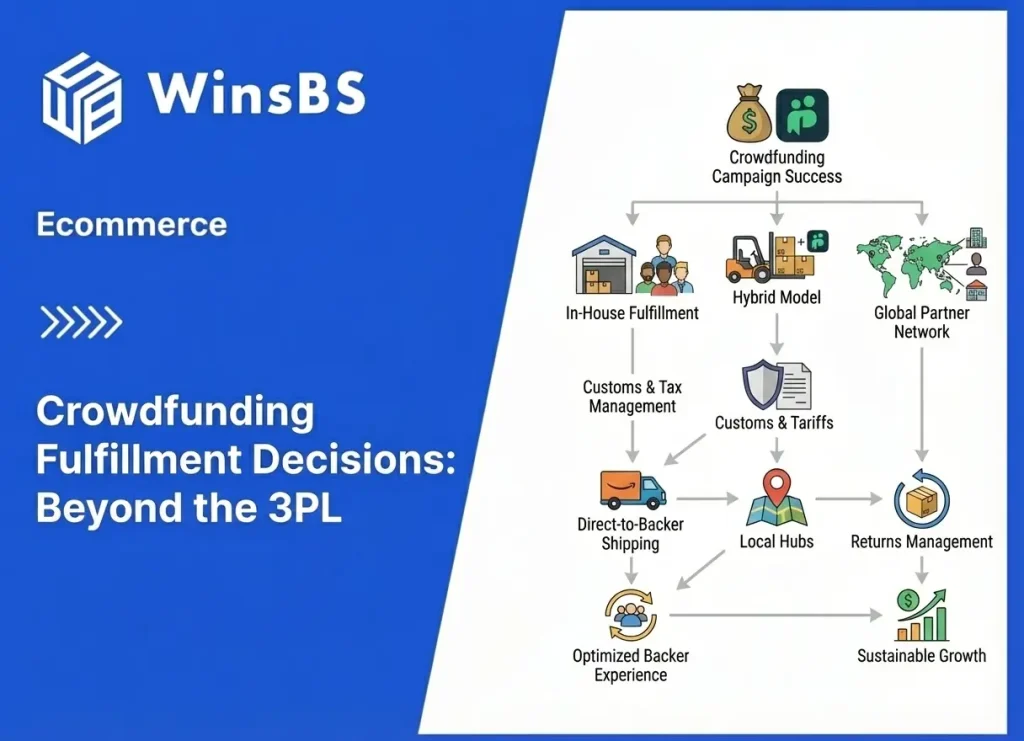

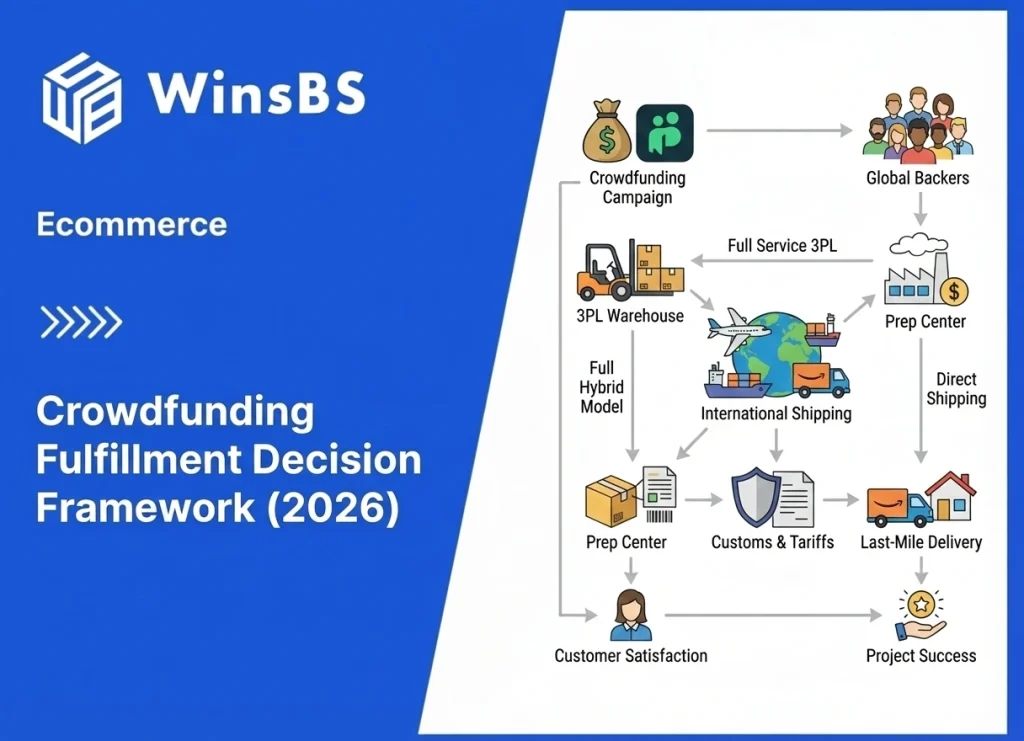

Indiegogo Fulfillment: Continuous Demand Risk Why ongoing orders turn fulfillment commitments into structural exposure Crowdfunding Fulfillment Risk Analysis · WinsBS Research Most Indiegogo fulfillment failures are not triggered by late shipments, warehouse mistakes, or carrier disruptions. They begin much earlier, at the moment teams assume that demand will eventually stop changing. In traditional crowdfunding environments, that assumption is usually safe. Orders accumulate during a defined campaign window. The campaign closes. Demand stabilizes. Fulfillment decisions are then made against a dataset that no longer moves. Indiegogo breaks that sequence. Once a campaign enters InDemand , orders can continue indefinitely. There is no structural signal that demand has finished forming. At first, this feels like upside. More time. More orders. More reach. Structurally, however, the fulfillment problem changes. Fulfillment is no longer preparing for a closed dataset. It is operating while the dataset itself continues to evolve. When demand does not converge, fulfillment stops being a phase. It becomes an ongoing state. Why Continuous Demand Changes the Fulfillment Problem Crowdfunding fulfillment is typically treated as a project. Demand is collected. Execution follows. That separation is what allows early commitments to feel safe. In Indiegogo InDemand campaigns, that boundary disappears. Orders continue to arrive while fulfillment planning and execution are already underway. When demand remains open, fulfillment is no longer a project-based task. It becomes an operational condition that persists while decisions are being executed. This shift matters because most fulfillment models assume closure. They are designed around a moment when demand stops changing and execution can proceed against a stable input set. Batch-based fulfillment assumptions fail under continuous demand because the system never receives a final dataset to execute against. This pattern mirrors a broader decision-timing failure observed across crowdfunding environments: outcomes break down not due to execution quality, but because irreversible commitments are made while key variables are still moving. InDemand Keeps Demand Open, But Fulfillment Decisions Get Frozen Indiegogo’s InDemand structure introduces rolling order intake. Late backers arrive after the campaign. SKU preferences continue to shift. Destination mixes evolve as new regions contribute demand. The data continues to move. Fulfillment decisions do not. To function at all, fulfillment systems require commitment. Packaging formats must be finalized. Routing logic must be selected. Inventory must be positioned somewhere. These decisions are typically made early, because execution cannot proceed without them. In continuous demand environments, data remains fluid while fulfillment decisions are structurally forced to freeze. This creates a mismatch. The system continues to ingest new inputs, but executes against rules designed for an earlier demand snapshot. Data flow and decision flow decouple under continuous demand, creating structural exposure rather than operational inefficiency. Why Batch-Based Fulfillment Models Break Batch-based fulfillment models assume containment. Demand enters the system, is processed, and exits. Variability exists, but it is bounded by the campaign lifecycle. Continuous demand removes that containment. There is no final batch. Fulfillment becomes a loop rather than a sequence. When breakdowns appear, they are often misattributed to execution problems. Inventory imbalances surface. Rerouting overhead grows. Exception queues expand. These failures do not indicate poor execution. They indicate that a batch-based model is being applied in an environment where demand never fully closes. Indiegogo campaigns routinely experience rolling volume changes, backorders, and expanding demand channels , extending variability instead of resolving it. When fulfillment models depend on closure, continuous demand transforms variability into systemic backlog. Where Early Commitment Amplifies Risk In continuous demand environments, the most damaging failures are not isolated mistakes. They are commitments that get executed repeatedly. Packaging assumptions, routing rules, and inventory positioning decisions all carry inertia. Once embedded in the system, reversing them requires cost, delay, or disruption. Under continuous demand, early fulfillment commitments are replayed indefinitely against changing inputs. In a closed campaign, this risk is limited. Under InDemand conditions, there is no natural stopping point. Each new order re-applies earlier assumptions to present-day demand realities. Early commitment does not merely introduce risk; it amplifies risk through repetition. What Can Be Evaluated Without Commitment Continuous demand does not eliminate analysis. It changes where analysis must stop and where commitment becomes dangerous. Demand volatility can be observed. SKU mix drift can be tracked. Destination distribution can be monitored. These activities increase clarity without forcing the fulfillment system into irreversible execution rules. What cannot be safely committed while demand remains open is the execution logic that will be applied repeatedly. Premature commitment does not reduce uncertainty. It converts uncertainty into structural exposure. For broader Indiegogo fulfillment context without shifting focus away from continuous demand risk, see Indiegogo Fulfillment . Where This Article Fits — Crowdfunding Fulfillment Decision Framework This article is part of a broader Crowdfunding Fulfillment Decision Framework. It isolates one structural variable: how continuous demand amplifies fulfillment risk when execution commitments are made too early in Indiegogo campaigns. It is written as a decision-layer reference. It does not explain how to use InDemand, how to manage shipping waves, or how to optimize fulfillment operations. The full framework examines how demand behavior, decision timing, structural variability, and execution responsibility interact across different crowdfunding environments. Crowdfunding Fulfillment Decision Framework (Hub) Related framework pages validate additional variables such as SKU-driven variance, cost volatility, and fulfillment partner selection, without collapsing the framework into an execution guide.